Experience in repairing worn main shafts of glassware cleaning machines

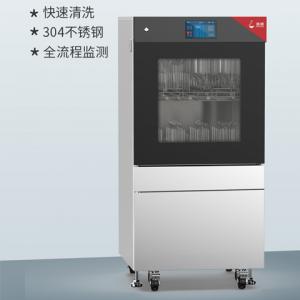

A glassware cleaning machine, also known as a bottle washing machine, consists of a stainless steel water pump, a high-pressure nozzle, an electrical box, and so on. Equipment suitable for brush cleaning and water flushing cleaning of glass bottles, plastic bottles, etc., whether used alone or in combination, has been widely used in laboratory production. Today, the editor will mainly talk about the causes of wear on the spindle of the bottle washing machine and corresponding maintenance measures.The spindle of the bottle washing machine is worn, not only the bearing position is worn, but also the water seal position is worn. Due to the overall thinning of the shaft, there is a gap between the water seal and the shaft, as well as a gap between the inner ring of the bearing and the bearing position. Therefore, cleaning solution (including alkaline solution) leaks outward from the sealing position through the gap between the shaft and the bearing position, seriously affecting the production environment and personnel safety in the workshop.

Before the maintenance, we also processed the spare parts for the spindle of the glassware cleaning machine, but the disassembly difficulty of the spindle is very high, so it can only be repaired online. We will share our repair experience with you.

The steps for quickly repairing the wear of the bottle washing machine shaft online are as follows:

1. The wear size of the bearing position measured on site is 0.1mm-0.3mm;

2. Surface treatment, removing the oxide layer and oil stains on the surface;

3. Using point positioning repair technology on site for repair;

4. Mark positioning points on site to determine the repair concentricity;

5. Mix SD7104 material and apply it to the surface of the shaft;

6. Apply release agent to the surface of the inner ring of the bearing and let it dry;

7. Install bearings;

8. After the material has solidified, start up and run for use.

Precautions for maintenance of glassware cleaning machine:

1. According to the maintenance requirements of the bottle washing machine: add lubricating grease to the bearings of the sleeve roller chain, bottle inlet system, bottle outlet system, and return device every shift; Add lubricating grease to other bearings such as chain box drive shaft and universal joint every two shifts; Each gearbox should be checked for lubrication once a quarter and the lubricating oil should be replaced if necessary.

2. Regular attention should be paid to observing whether the movements of various parts are synchronized, whether there are abnormal noises, whether the fasteners are loose, whether the liquid temperature and level meet the requirements, whether the water pressure and steam pressure are normal, whether the nozzles and filters are blocked and cleaned, whether the bearing temperature is normal, and whether the lubrication is good. Once abnormal situations are found, they should be dealt with promptly.

3. Every time the washing solution is changed or wastewater is discharged, the machine should be thoroughly flushed to remove dirt and broken glass, and the filter cartridge should be cleaned and cleared.

4. Spray the heater with high-pressure water once a quarter, and clean the dirt filter and liquid level detector on the steam pipeline once.

5. Brush the nozzle every month, unclog the nozzle, and adjust the alignment of the nozzle in a timely manner.

6. Check various chain tensioners every six months and adjust them as needed.