The difference between Laboratory glassware washer and ultrasonic cleaning machines

Principle:

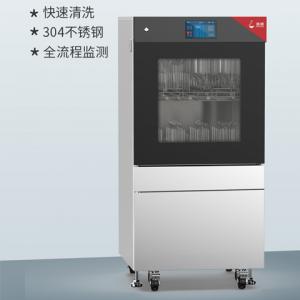

Laboratory glassware washer: Place the glassware on a water outlet sprinkler and use high-pressure hot water to spray and wash them, in conjunction with professional cleaning agents, Then can be rinsed and dried.

Ultrasonic cleaning machines: Soak the glassware in a sink and use ultrasonic vibration to clean them. No rinsing and drying function.

Cleaning process:

Laboratory glassware washer: Main cleaning - neutralization cleaning - rinsing - drying, fully automated completion, glassware can be directly used after washing.

Ultrasonic cleaning machines: Only the cleaning step requires manual rinsing, it requires manual rinsing and then drying in an oven, with a low degree of automation.

Cleaning results:

Laboratory glassware washer: Select the corresponding program for cleaning, ensure cleanliness, and the cleaning data can be recorded

Ultrasonic cleaning machine: The cleanliness is greatly affected by manual operation, and there is no cleaning record, and may cause cracks, bubbles, etc. on the vessels, affecting the use of volumetric vessels such as volumetric flasks.

From this, it can be seen that the advantages of laboratory glassware washer over ultrasonic cleaning machines are obvious:

Efficient: Based on the characteristics of the glassware, a dedicated cleaning basket can continuously spray the inner and outer walls of the utensils, and achieve large-scale cleaning.

Safety: Reduces the harm of cleaning agents and pollutants to laboratory personnel.

Cleanliness: There are no dead corners on the inner and outer walls and the belly, and the cleaning effect can be verified.

After cleaning, it can be dried. Efficient HEPA filters and fans inject hot air into the interior of the glassware, and slender pipettes can also complete drying.

Traceability: The records of each cleaning are kept intact for easy traceability management