Discussion on the Promotion of Chemical Cleaning Technology for Petroleum and Petrochemical Instruments

Abstract: In the production process of petroleum and petrochemical products, due to their special physical and chemical properties, as well as the complex composition of derivatives, the cleaning of instruments in petroleum and petrochemical production and quality inspection processes becomes complex and difficult. Usually, cleaning personnel use various cleaning methods such as soaking in solution, brushing with a brush, ultrasonic cleaning, laundry detergent, and detergent to carry out cleaning work. The manual cleaning method explored based on cleaning experience has a certain cleaning effect, but its efficiency is low, cost is high, and it may pose great harm to cleaning personnel, which cannot be ignored. With the development of technology, we urgently need a new, safer, simpler, and more effective cleaning process technology to provide strong support for the production of petroleum and petrochemical industry. For this purpose, we have launched fully automatic petroleum and petrochemical dedicated cleaning equipment (Q900 series, P2900 series) to achieve high flux fully automated cleaning, shorten cleaning cycles, reduce costs, protect the health of operators, and improve cleaning efficiency.Common petrochemical oils: gasoline, diesel, kerosene, oil coke, lubricating oil, engine oil, turbine oil, gear oil, viscosity oil, etc

Common utensils: sampling bottles 500ml, 1000ml, 2000ml; 250ml, 500ml, 1000ml round bottomed flasks; 250ml, 500ml, 1000ml triangular bottles; Beaker 500ml, 1000ml, 2000ml; Measuring cylinder 500ml, 1000ml; Pipette 1-50ml, 2ml injection bottle, etc. The cleaning capacity of sampling bottles shall not be less than: 60 per 1000ml/75 per 500ml; 126 250ml volumetric flasks

Cleaning process: The bottle washing machine in the language bottle laboratory automatically cleans, rinses, and dries (i.e. pre washing - alkaline washing - neutralization washing - rinsing 1- rinsing 2- drying), with one click settings and automatic cleaning and drying.

Cleaning conditions: Power supply: 220V or 380V, tap water (for cleaning), purified water (according to cleaning cleanliness requirements), drainage outlet or floor drain

Cleaning principle: The physical action of circulating water spray cleaning+the saponification reaction and emulsification reaction of the cleaning solution+the cleaning effect of automatic heating acceleration.

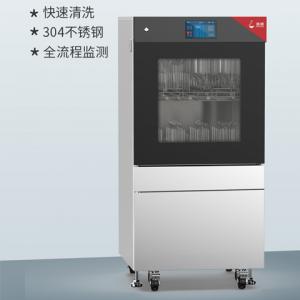

Saponification reaction: The saponification reaction between the oil and the degreasing alkali in the cleaning solution transforms the previously insoluble synthetic oil into soap and glycerol that are soluble in water (especially hot water). When using saponification reaction for degreasing and oil removal, the oil removal is thorough, the effect is rapid, the cost is low, and the operation is simple and convenient; When emulsification is used for degreasing and oil removal, the oil itself is not soluble in water. The contradiction between its hydrophilic and oleophilic groups lies between water and oil, and small oil droplets are evenly distributed in the solution to achieve the purpose of oil removal. This method thoroughly removes oil, is fast, efficient, and has mild physicochemical properties of the cleaning solution.Bottle washing machine

Notes on essential functions for selection:

1. The language bottle laboratory bottle washing machine has a large capacity, and each layer can clean 250ml volumetric bottles and 500ml containers (large and small containers can be placed, but small capacity equipment is not sufficient, and the equipment capacity is not determined by the number of cleaning layers)

2. The device screen monitors and displays the online pipeline pressure value in real-time, and monitors the normal spray water pressure value to ensure effective spray cleaning effect